Manufacturing Facilities

Gowell Rubber Industries is equipped with total 70 number of production machines which includes, Injection Moulding (160~250 Ton), Vacuum Compression Mouldings (100~350 Ton) and Compression Mouldings (80~200 Ton). Mixing Section is equipped with Semi-Automatic Chemical Weighing System and very soon will be upgraded to Auto dispensing of Carbon, Fillers and Oils directly to Kneaders.

We have inhouse Grit blasting facility for Metal surface preparation and Automatic Adhesive Spray coating machine.

4 KNEADERS

25~55 LTRS CAPACITY

1

PREFORMER

5 MIXING MILLS

UPTO 16X42 SIZE

2

STRIP CUTTER

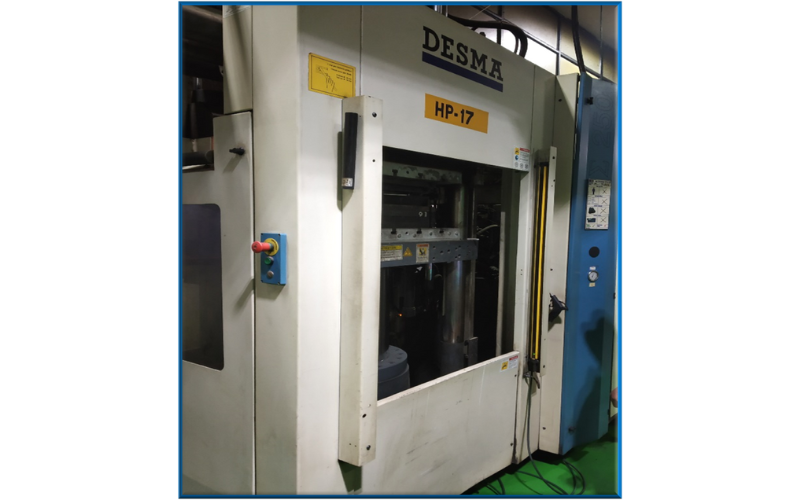

5 INJECTION

MOLDING MACHINES

(160 ~250 TON)

64 VACUUM

COMPRESSION MACHINES

(100~350 TON)

Purpose: Removes oxide coatings. Increasing the surface area and activates the surface with steel grit.

CRYOGENIC MACHINE

MAKE : NISSANKI, JAPAN

CAPACITY : 20 Ltr

TRIMMING MACHINE

CONCEPT: AERODYNAMICS

APPLICATION RANGE: dia 3-80 mm